Manual Band Saws Industrial

Manual Band Saws Correctional

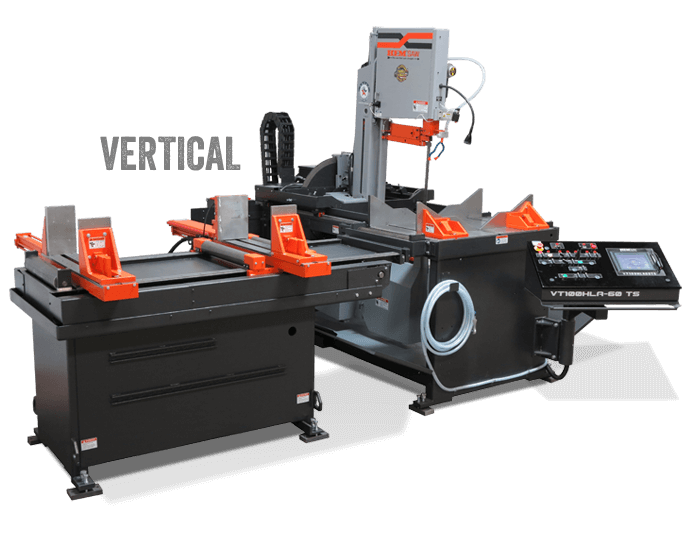

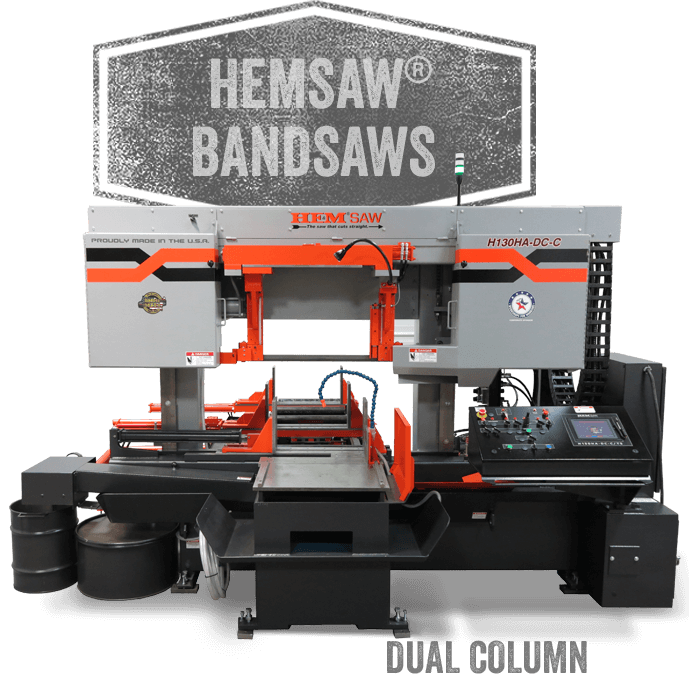

A floor-standing saw will make it much easier to make complex cuts or rip large items.

A good example is using the bandsaw in order to cut large pieces from lumber into similar-sized fence pieces.